安裝維護

正確地使用產品能夠獲得更佳的產品體驗。

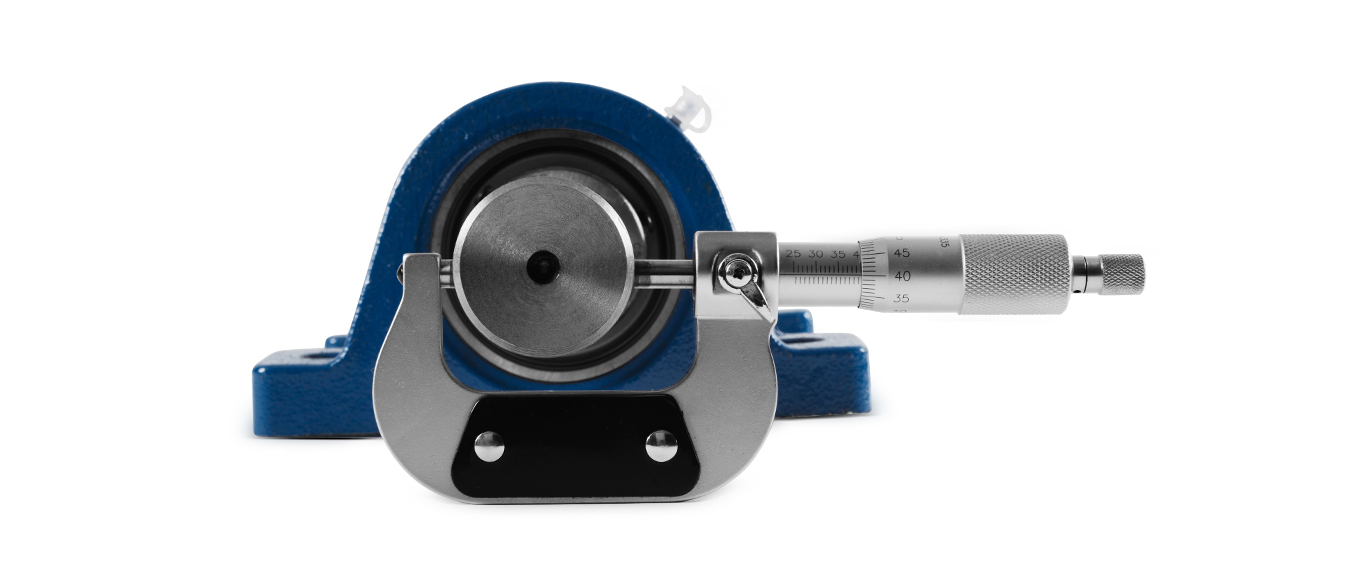

檢查底座的剛性、安装面的平面度、轴的尺寸公差等是否合格。

安裝軸公差推薦表

| 軸徑 | UK系列 | ||||||

| 軸推薦公差(h9) | |||||||

| mm | in | μm | in | ||||

| > | ≤ | > | ≤ | max | min | max | min |

| 10 | 18 | 7/16 | 11/16 | 0 | -43 | 0 | -0.0017 |

| 18 | 30 | 3/4 | 1-1/8 | 0 | -52 | 0 | -0.0021 |

| 30 | 50 | 1-3/16 | 1-15/16 | 0 | -62 | 0 | -0.0024 |

| 50 | 80 | 2 | 3-1/8 | 0 | -74 | 0 | -0.0029 |

| 80 | 120 | 3-3/16 | 4-11/16 | 0 | -87 | 0 | -0.0034 |

| 120 | 180 | 4-3/4 | 7-1/16 | 0 | -100 | 0 | -0.0039 |

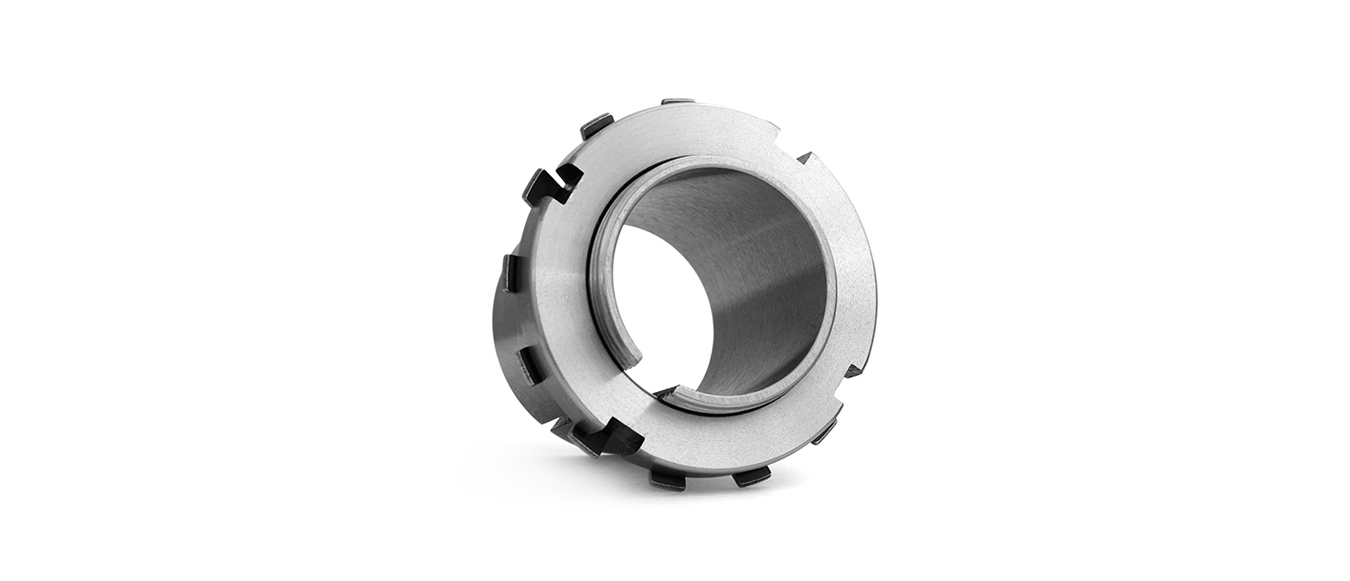

將緊定套上的鎖緊螺母、锁紧垫圈拆分。

將緊定套插入到軸上,置于所定带座轴承的安装位置。

緊定套插入困難時,可把螺丝刀等插入紧定套的槽口部位扩大槽口使其容易插入。

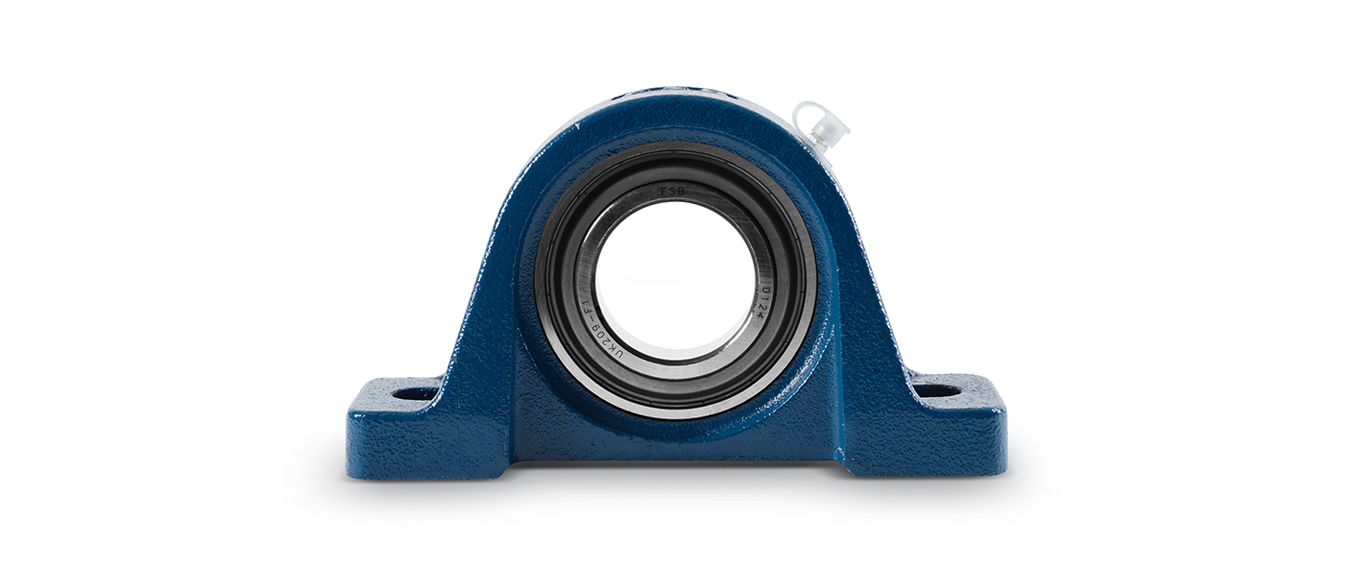

將帶座軸承插入軸上,置于所定位置。

用扭矩扳手按規定的鎖緊扭矩將軸承座的安裝螺栓擰緊。

軸承座安裝螺栓鎖緊扭矩推薦表

| 螺栓公稱型號 | 鎖緊扭矩(±10%) | |||

| mm | in | N.m | lbf.in | lbf.ft |

| M6 | 1/4 | 4.0 | 33 | 3 |

| M8 | 5/16 | 8.0 | 71 | 6 |

| M10 | 3/8 | 17 | 151 | 13 |

| M12 | 7/16 | 29 | 257 | 21 |

| M14 | 1/2 | 47 | 416 | 35 |

| M16 | 5/8 | 73 | 646 | 54 |

| M18 | - | 107 | 947 | 79 |

| M20 | 3/4 | 145 | 1280 | 107 |

| M22 | 7/8 | 200 | 1770 | 148 |

| M27 | 1 | 372 | 3290 | 275 |

| M30 | 1-1/8 | 500 | 4430 | 369 |

| M33 | 1-1/4 | 690 | 6110 | 509 |

| M36 | 1-3/8 | 880 | 7790 | 649 |

備註:适用于P,F,FS,FL,FC,FT,FA,FB,LF,FD轴承座

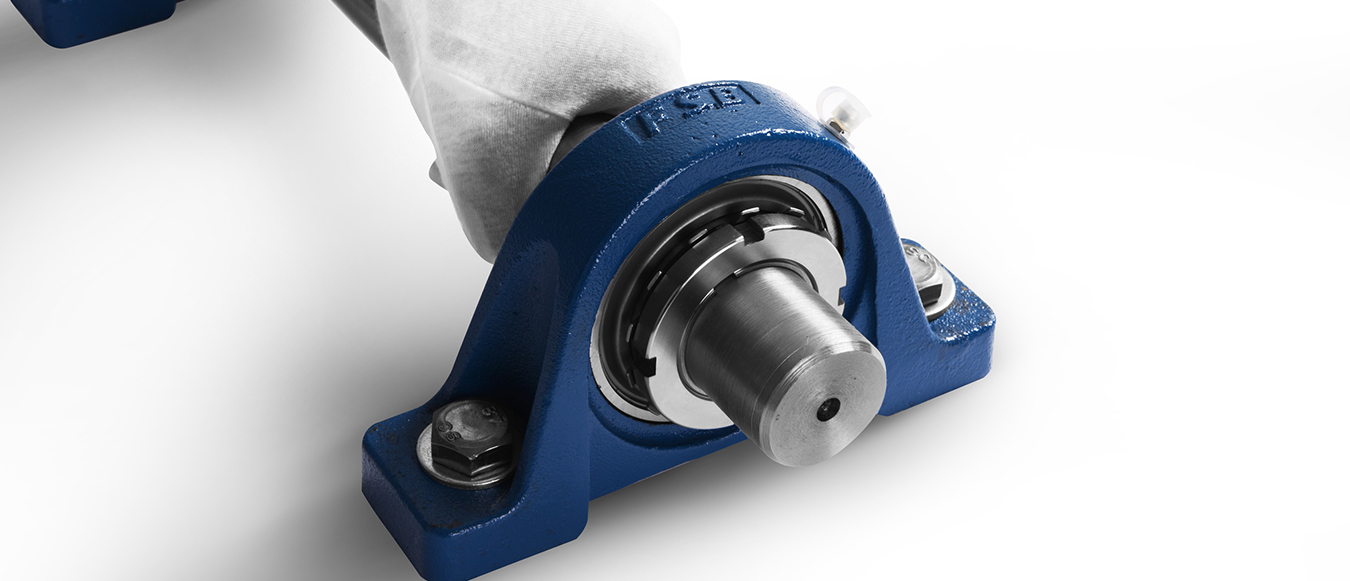

在緊定套上安裝鎖緊墊圈和鎖緊螺母,用手拧紧锁紧螺母

用扭矩扳手按規定的鎖緊扭矩將緊定套的鎖緊螺母擰緊

鎖緊螺母鎖緊扭矩推薦表

| 內徑型號 | 使用條件:普通载荷(Crx0.12>Pr) | |||||||||||

| UK200锁紧扭矩(±10%) | UKX00锁紧扭矩(±10%) | UK300锁紧扭矩(±10%) | ||||||||||

| N·m | lbf.in | lbf.ft | Cr(KN) | N·m | lbf.in | lbf.ft | Cr(KN) | N·m | lbf.in | lbf.ft | Cr(KN) | |

| 05 | 32 | 283 | 24 | 14 | 44 | 389 | 33 | 19.5 | 38 | 336 | 28 | 21.2 |

| 06 | 38 | 336 | 28 | 19.5 | 50 | 443 | 37 | 25.5 | 57 | 505 | 42 | 26.7 |

| 07 | 50 | 443 | 37 | 25.5 | 63 | 558 | 47 | 30.7 | 75 | 664 | 55 | 33.4 |

| 08 | 63 | 558 | 47 | 30.7 | 94 | 832 | 69 | 33.2 | 100 | 885 | 74 | 40.7 |

| 09 | 75 | 664 | 55 | 33.2 | 94 | 932 | 69 | 35.1 | 150 | 1330 | 111 | 48.9 |

| 10 | 94 | 832 | 69 | 35.1 | 138 | 1220 | 102 | 43.6 | 188 | 1660 | 139 | 62 |

| 11 | 125 | 1110 | 92 | 43.6 | 175 | 1550 | 129 | 52.7 | 225 | 1990 | 166 | 71.6 |

| 12 | 163 | 1440 | 120 | 52.7 | 207 | 1830 | 153 | 57.2 | 281 | 2490 | 207 | 81.9 |

| 13 | 188 | 1660 | 139 | 57.2 | 244 | 2160 | 180 | 66.3 | 331 | 2930 | 244 | 92.7 |

| 15 | 213 | 1890 | 157 | 66.3 | 269 | 2380 | 199 | 72.8 | 469 | 4150 | 346 | 113 |

| 16 | 250 | 2210 | 185 | 72.8 | 319 | 2820 | 235 | 83.2 | 563 | 4980 | 415 | 123 |

| 17 | 275 | 2430 | 203 | 83.2 | 369 | 3270 | 272 | 95.6 | 663 | 5870 | 489 | 133 |

| 18 | 325 | 2880 | 240 | 95.6 | 425 | 3760 | 314 | 109 | 763 | 6750 | 563 | 143 |

| 19 | - | - | - | - | - | - | - | - | 888 | 7860 | 655 | 153 |

| 20 | - | - | - | - | 613 | 5430 | 452 | 133 | 1110 | 9800 | 817 | 173 |

| 22 | - | - | - | - | - | - | - | - | 1530 | 13500 | 1130 | 205 |

| 24 | - | - | - | - | - | - | - | - | 1840 | 16300 | 1360 | 207 |

| 26 | - | - | - | - | - | - | - | - | 2210 | 20500 | 1710 | 229 |

| 28 | - | - | - | - | - | - | - | - | 2690 | 23800 | 1980 | 253 |

| 內徑型號 | 使用條件:普通载荷(Crx0.12<Pr) | |||||||||||

| UK200锁紧扭矩(±10%) | UKX00锁紧扭矩(±10%) | UK300锁紧扭矩(±10%) | ||||||||||

| N·m | lbf.in | lbf.ft | Cr(KN) | N·m | lbf.in | lbf.ft | Cr(KN) | N·m | lbf.in | lbf.ft | Cr(KN) | |

| 05 | 56 | 496 | 41 | 14 | 79 | 699 | 58 | 19.5 | 68 | 602 | 50 | 21.2 |

| 06 | 68 | 602 | 50 | 19.5 | 90 | 767 | 66 | 25.5 | 101 | 894 | 75 | 26.7 |

| 07 | 90 | 767 | 66 | 25.5 | 113 | 1000 | 83 | 30.7 | 135 | 1200 | 100 | 33.4 |

| 08 | 113 | 1000 | 83 | 30.7 | 169 | 1500 | 125 | 33.2 | 180 | 1590 | 133 | 40.7 |

| 09 | 135 | 1200 | 100 | 33.2 | 169 | 1500 | 125 | 35.1 | 270 | 2390 | 199 | 48.9 |

| 10 | 169 | 1500 | 125 | 35.1 | 248 | 2200 | 183 | 43.6 | 338 | 2990 | 249 | 62 |

| 11 | 225 | 1990 | 166 | 43.6 | 315 | 2790 | 232 | 52.7 | 405 | 3590 | 299 | 71.6 |

| 12 | 293 | 2593 | 216 | 52.7 | 371 | 3280 | 274 | 57.2 | 506 | 4480 | 373 | 81.9 |

| 13 | 338 | 2990 | 249 | 57.2 | 439 | 3890 | 324 | 66.3 | 596 | 5280 | 440 | 92.7 |

| 15 | 383 | 3390 | 283 | 66.3 | 484 | 4280 | 357 | 72.8 | 844 | 7470 | 623 | 113 |

| 16 | 450 | 3980 | 332 | 72.8 | 574 | 5080 | 424 | 83.2 | 1010 | 8970 | 748 | 123 |

| 17 | 495 | 4380 | 365 | 83.2 | 664 | 5880 | 490 | 95.6 | 1190 | 10600 | 880 | 133 |

| 18 | 585 | 5180 | 432 | 95.6 | 765 | 6770 | 565 | 109 | 1370 | 12200 | 1010 | 143 |

| 19 | - | - | - | - | - | - | - | - | 1600 | 14100 | 1180 | 153 |

| 20 | - | - | - | - | 1103 | 9760 | 814 | 133 | 1990 | 17600 | 1470 | 173 |

| 22 | - | - | - | - | - | - | - | - | 1750 | 24300 | 2030 | 205 |

| 24 | - | - | - | - | - | - | - | - | 3310 | 29300 | 2440 | 207 |

| 26 | - | - | - | - | - | - | - | - | 3980 | 35300 | 2940 | 229 |

| 28 | - | - | - | - | - | - | - | - | 4840 | 42800 | 3570 | 253 |

| Cr=基本额定动载荷,Pr=当量动载荷 | ||||||||||||

將和鎖緊螺母外徑面的缺口位置相一致的墊圈的爪(1枚)折弯在锁紧螺母外径面的缺口位置,进行锁紧螺母的防松处理。

用手轉動軸,确认轴承的旋转状态是否异常。